PU synthetic leather has the characteristics of soft and natural luster, soft hand feeling and strong leather feeling. It is more and more used to make colourful and fashionable leather garments, leather bags and light and comfortable leather shoes, which meets the needs of consumers to improve their quality of life.

However, consumers do not know that the main raw material used in the production of PU synthetic leather, polyurethane resin, is produced in a polluted environment. The source of pollution is mainly caused by the volatilization of solvent solvents in the production process. How to solve the contradiction between consumer demand and production environment pollution? In a recent interview, the reporter learned that the synthetic leather industry is embarking on a technological revolution that replaces solvent with water.

Pollution is due to “solvent”

“Every time I go to the tannery, I feel uncomfortable. As long as I go to the synthetic leather production workshop, I can smell a pungent smell.” A scientific person who has been engaged in synthetic leather research for a long time said with emotion. His experience is the current state of production environment in China’s synthetic leather industry.

PU synthetic leather, accurately referred to as polyurethane synthetic leather. The traditional polyurethane synthetic leather (PU synthetic leather) uses polyurethane resin to produce the surface layer and the base material of the synthetic leather, and adopts a coating process in the production process. The polyurethane resin is obtained by a polymerization method using benzene, ketone, ethyl acetate, dimethylformamide or the like as a main solvent. The polyurethane produced by this process is also called a solvent-type polyurethane resin. These oily solvents have become the main source of pollution.

The reporter learned in the interview that at present, China has nearly 2,000 large and small synthetic leather production enterprises, basically using solvent-based resin production. The solvent-based polyurethane resin contains 70% to 80% of toxic and harmful organic solvents such as dimethylformamide and toluene, which are highly volatile in the production process and become organic waste gas, causing air pollution. A large amount of water is also needed in the production process, which also causes surface water pollution. In order to reduce pollution, it is necessary to recover organic solvents in waste gas and waste water, resulting in new pollutants – hazardous solid waste and organic waste gas, waste water and other pollution. It is estimated that the national synthetic leather industry emits more than 200,000 tons of organic waste gas per year, more than 8 million tons of waste water, and more than 50,000 tons of dangerous waste. The use of solvent-based resin to produce synthetic leather not only brings environmental pollution, but also because some of its harmful substances remain in the product, resulting in poor quality of synthetic leather products, environmental protection indicators can not meet the requirements of international high-grade synthetic leather. Therefore, most of our products are also low-end products, which seriously affect the entry of synthetic leather products into the international market.

In addition to the pollution caused by solvent evaporation, the use of solvent-based polyurethane resin production and processing of synthetic leather, but also brings two major drawbacks: First, the problem of breathable and moisture permeable is not well solved, wearing on the body makes people feel stuffy and uncomfortable. Second, synthetic leather uses a large amount of chemical raw materials. Some chemical raw materials have certain toxicity and residual residues, which are potentially harmful to the human body. Countries such as Europe and the United States have thus erected green barriers and technical barriers to polyurethane PU synthetic leather in China.

It is understood that the global synthetic leather market scale is 50 billion to 70 billion US dollars, and China’s synthetic leather production accounts for more than 70% of the world’s total production capacity. At present, due to its excellent properties, polyurethane synthetic leather has become the best substitute for natural leather in the civilian field, and has also been applied in cutting-edge high-tech fields such as defense industry and aerospace. However, due to the fact that China’s current production is mainly solvent-based, the development of the synthetic leather industry has been constrained. The use of solvent-based polyurethane slurries has been reduced internationally, and the use of waterborne polyurethane (aqueous PU) slurries is gradually increasing.

Environmental protection depends on “water”

“The application of waterborne polyurethane resin in the synthetic leather industry has three major advantages.” Feng Yijun, deputy secretary general of the China Plastics Processing Industry Association and secretary general of the artificial leather synthetic leather special committee, said: “From the perspective of energy saving, the application of solvent-based polyurethane requires a recycling. The device, this recycling device requires water and electricity as well as labor and land; if water-based polyurethane is used, the whole recycling system can be saved and energy-saving; for environmental protection, clean production and environmental protection are now being implemented, and water-based polyurethane ( The application of water-based PU) makes the whole production process of synthetic leather more environmentally friendly. After the product is made, it meets the standards of the European Union, meets the requirements of safety and environmental protection, and does not harm the health of users. From the perspective of safety production, water-based polyurethane (aqueous PU) The replacement of solvent-based polyurethane (PU) in the synthetic leather industry reduces the safety hazard of solvent ignition in the synthetic leather manufacturing process, reduces the air pollution of the solvent, and reflects the responsibility of the producer.”

Xie Zhenming, executive deputy director of China Waterborne Resin and Waterborne Ecological Synthetic Leather R&D Center, and a visiting professor at Anhui University, told reporters that the use of waterborne polyurethane (waterborne PU) resin to produce synthetic leather not only meets international environmental standards in terms of chemical properties, but also in physical properties. It also greatly improves the performance of synthetic leather. The polymer chain of waterborne polyurethane (waterborne PU) enables the resin to have multiple functions: water resistance, solvent resistance, abrasion resistance, scratch resistance, wrinkle resistance, moisture permeability, gas permeability and feel. Synthetic leather made of resin is closer to the dermis.

It is understood that since Shell Company introduced water-based polyurethane dispersion leather finishing agent products into the Chinese market for the first time in 1978, the development of waterborne polyurethane in China has passed more than 30 years. The earliest companies in this field include Anhui University, Jiangsu Research Institute of Chemical Industry, Dandong Light Chemical Institute, Shenyang Research Institute of Chemical Industry, and Beijing Research Institute of Chemical Industry. Later, the production companies also participated, and Huai’an KAIYUE Technology Development Co., Ltd. began research on water-based polyurethane for synthetic leather. Since 2005, KAIYUE Chief Engineer has been involved in the polyurethane synthetic leather industry. In 2010, KAIYUE Technology produced synthetic leather waterborne surface treatment agent. In 2012, it produced synthetic polyurethane water-based polyurethane resin. In 2016, it captured water-based polyurethane resin. Polyurethane (water-based PU) synthetic leather preparation technical problems. In 2017, production of waterborne polyurethane (waterborne PU) synthetic leather began.

Despite the rapid development of domestic waterborne polyurethane synthetic leather, this process is not easy to push through the entire synthetic leather industry.

Feng Yijun said that the industry association will promote the application of waterborne polyurethane (waterborne PU) in the synthetic leather industry from three aspects: policy, industry leadership and standard setting. From the policy level, we must strive to include water-based polyurethanes in national technology encouragement projects and apply for energy-saving products and environmental protection equipment. At the same time, the Association is applying with the Ministry of Industry and Information Technology and other relevant departments to apply for the SME Technology Innovation Fund to support the development of water-based synthetic leather, production and application technology. Some provinces and municipalities have taken active measures in this regard, including Jiangsu Province, Zhejiang Province, and Guangdong Province, all of which are implementing ecological construction. The government has clear policy measures for adopting new environmental protection materials. From the perspective of the industry, the association will continue to establish some demonstration enterprises of ecological synthetic leather and bases for applying water-based synthetic leather, and organize exchanges and trainings of experts in the industry to promote the application of new technologies and new materials in the entire industry. From the aspect of standard setting, the association will formulate standards for enterprise ecological construction, including safety production standards and product standards.

Huai’an KAIYUE Technology Development Co., Ltd.

Water-based leather surface treatment agent, Eco-friendly, long-lasting wet wax feel, soft touch, non-slip KYS-088G

Water-based leather surface treatment agent, Eco-friendly, long-lasting wet wax feel, soft touch, non-slip KYS-088G

Simulation leather

Simulation leather

(中文) 水性超纤含浸树脂 超纤用水性树脂 不黄变反拨弹性佳磨毛手感柔滑

(中文) 水性超纤含浸树脂 超纤用水性树脂 不黄变反拨弹性佳磨毛手感柔滑

(中文) 水性超纤含浸树脂 超纤用水性聚氨酯树脂耐磨耐刮耐水解可染色性强

(中文) 水性超纤含浸树脂 超纤用水性聚氨酯树脂耐磨耐刮耐水解可染色性强

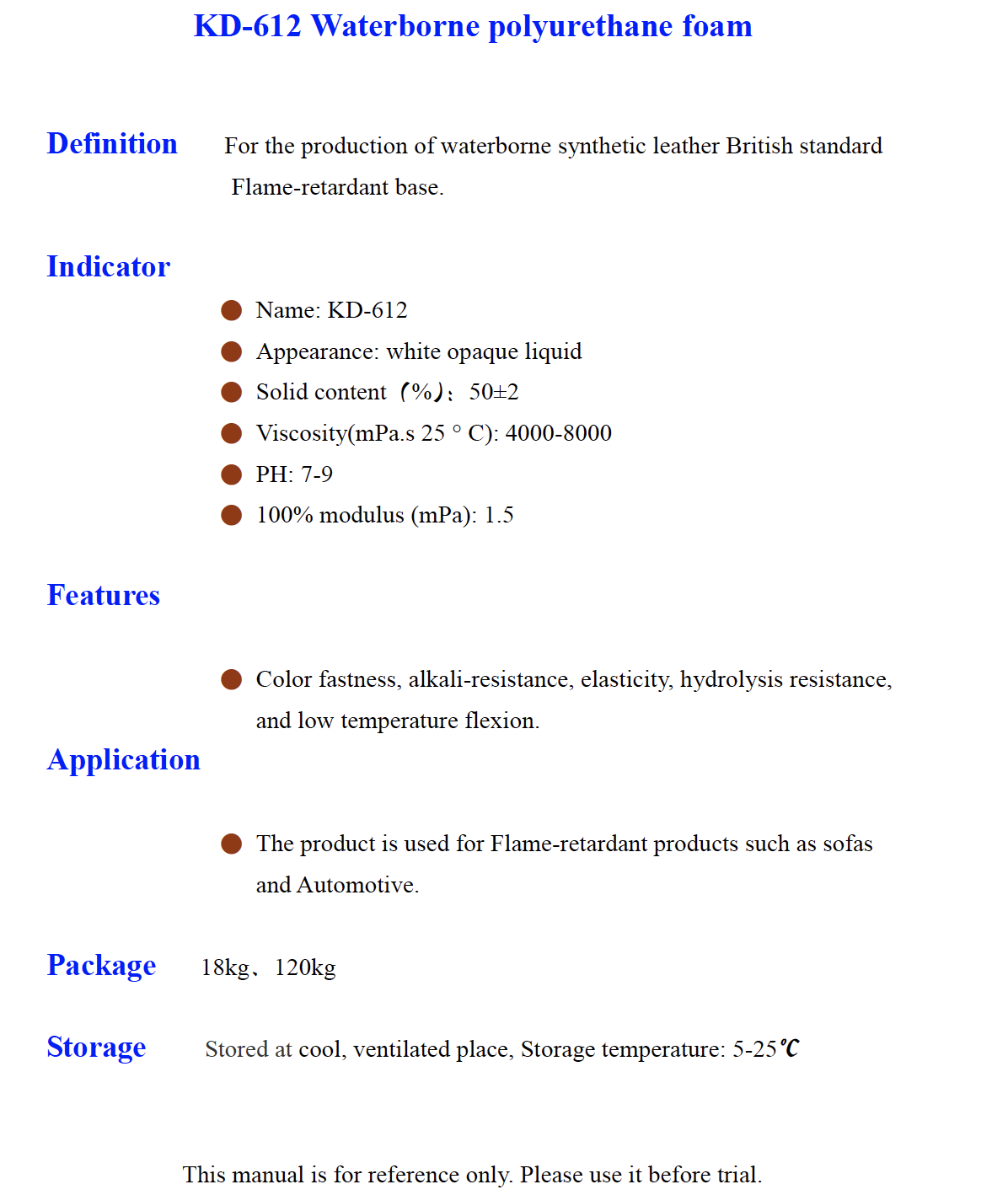

KD 612 Waterborne polyurethane foam

KD 612 Waterborne polyurethane foam

(中文) 水性超纤含浸树脂KYW-402 -用于超纤无纺布仿超纤革

(中文) 水性超纤含浸树脂KYW-402 -用于超纤无纺布仿超纤革

Water-based polyurethane foam is used to produce dry-process water-based synthetic leather

Water-based polyurethane foam is used to produce dry-process water-based synthetic leather

Automotive

Automotive