Increasingly strict environmental protection policies have restricted the development of solvent-based industries, making the water-based industry a hot industry. In order to cope with this problem, we found a lot of water-based resin when choosing a water-based resin, which dazzled ourselves. What are the water-based resins? What are the advantages? How should I choose water-based resin? Huai’an Hyatt Technology Development Co., Ltd. employees summarized some common water-based resins, hoping to help you further understand water Resin, in order to better choose the right water resin.

Waterborne Polyurethane Resins

Waterborne polyurethanes can be classified into anionic waterborne polyurethanes, cationic aqueous polyurethanes, and nonionic aqueous polyurethanes. Among them, anionic production is the largest and the most widely used. Anionic waterborne polyurethanes can be further divided into two major categories: carboxylic acid type and sulfonic acid type. In recent years, nonionic waterborne polyurethanes have been increasingly studied in macromolecular surfactants and associative thickeners. The cationic water-based polyurethane has good permeability, antibacterial and anti-mildew properties, and is mainly used for leather finishing agents.

Synthetic monomer

Waterborne polyurethanes can be classified into polyether type, polyester type, polycarbonate type, and polyether and polyester mixed type. Depending on the choice of diisocyanate, the waterborne polyurethane can be further classified into aromatic, aliphatic, araliphatic and alicyclic groups, or specifically classified into TDI type, IPDI type, MDI type, and the like. Aromatic waterborne polyurethane similar to oily polyurethane has obvious yellowing, poor weather resistance, and is a low-end popular product; aliphatic waterborne polyurethane has good color retention, weather resistance, but high price, belonging to high-end products; The properties of the araliphatic and alicyclic groups are between the two.

In the 1990s, with the environmental awareness and environmental protection regulations, the research and development of environmentally friendly waterborne polyurethanes have received increasing attention. Their applications have been extended from leather coating agents to coatings, adhesives, etc. The market for polyurethanes represents the development direction of coatings and adhesives. Surprisingly, in waterborne resins, waterborne polyurethanes are still representative of excellent resins and one of the hotspots in modern waterborne resins.

KM-123 waterborne polyurethane fabric

Overview: Gives the product a super soft, skin feel and dry feel.

Features: anti-yellowing, alkali resistance, hydrolysis resistance, low temperature flexion.

Use expansion: for skin contact products, garment leather and other products.

KD-610 Waterborne Polyurethane Foam

Overview: For the production of water-based synthetic leather bass.

Features: anti-yellowing, alkali resistance, soft handfeel, good elasticity, hydrolysis resistance, low temperature flexion.

Use expansion: for clothing, luggage, sofas, automotive leather, shoe leather and other products.

KD-612 Waterborne Polyurethane Foam

Overview: For the production of water-based synthetic leather British standard flame retardant bass.

Features: anti-yellowing, alkali resistance, good elasticity, hydrolysis resistance, low temperature flexion.

Use expansion: used for sofas, automotive leather and other requirements for flame retardant products.

KX-F325 Leveling wetting agent

KX-F325 Leveling wetting agent

Water-based rubber plastic mold release agent 40% anionic emulsion KX-495 Kai Xun

Water-based rubber plastic mold release agent 40% anionic emulsion KX-495 Kai Xun

Waterborne PU leather for shoes lining

Waterborne PU leather for shoes lining

For Shoes&HandbagIII

For Shoes&HandbagIII

PU synthetic leather water-based super bright treatment

PU synthetic leather water-based super bright treatment

Dry and wet method PU resin modifier, feel agent, leather chemical additives KY-3133

Dry and wet method PU resin modifier, feel agent, leather chemical additives KY-3133

柔软剂

柔软剂

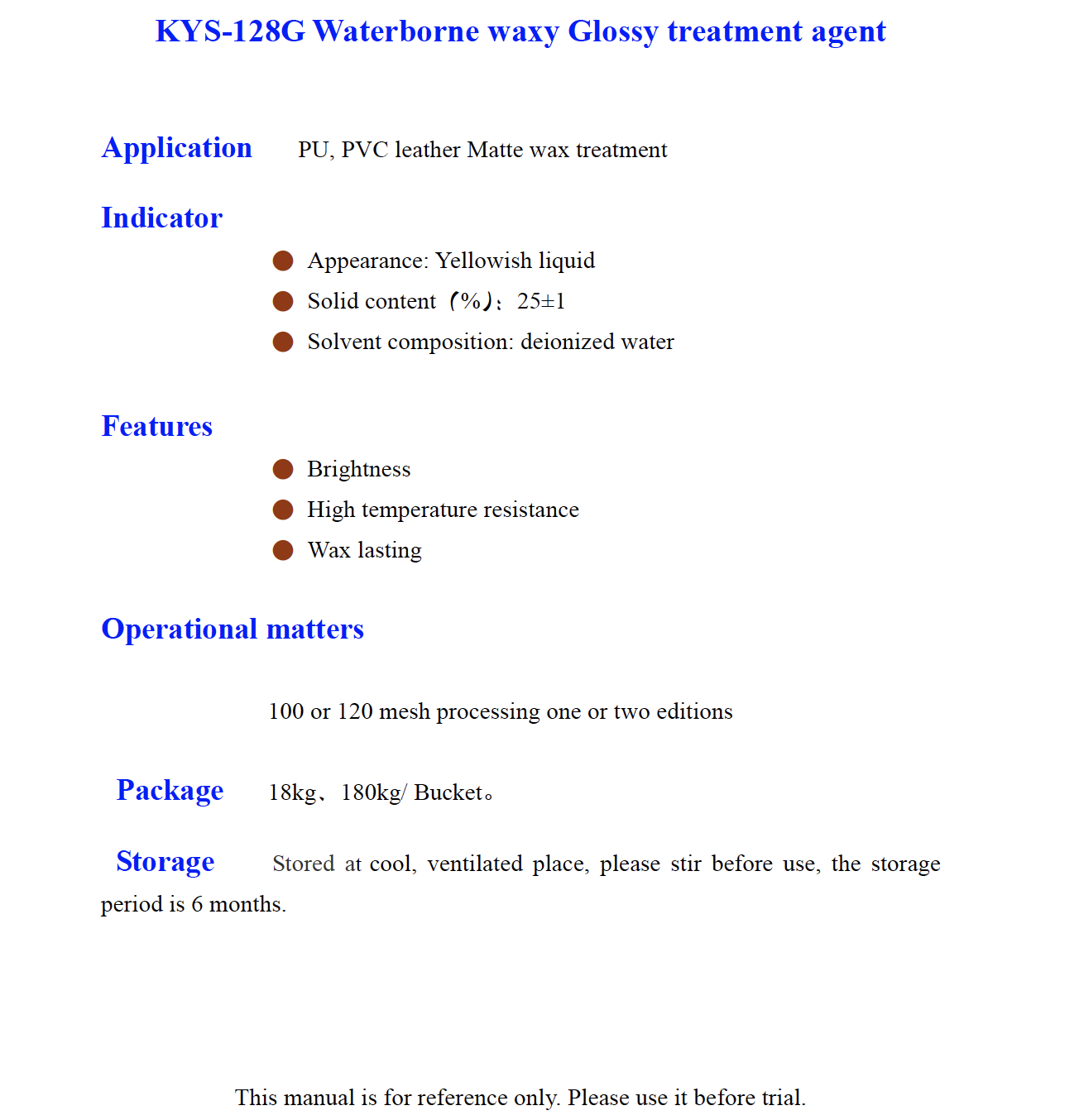

KYS 128G Waterborne waxy Glossy treatment agent

KYS 128G Waterborne waxy Glossy treatment agent