With the increasing awareness of environmental protection, consumers are no longer unfamiliar with the use of renewable materials, and they are more and more willing to accept renewable materials. Nowadays, many auto companies have applied renewable materials to automobiles, and recycled materials have become the darlings of auto companies.

Recently, a whole new generation of Audi A3 was launched. The new A3 uses renewable materials in its seats and insoles. Among them, 89% of the fabric material in the seat is made of recycled PET plastic bottles, which are spun and processed into yarn. It is reported that each seat uses up to 45 PET plastic bottles with a capacity of 1.5 liters, and Audi officials also said that this environmentally friendly fabric material is almost no different from traditional interior materials in terms of vision and touch.

In addition to seats, the carpet of the new generation Audi A3 also uses recycled PET plastic bottles, and this environmentally friendly material is also found in insulation materials, heat absorption layers, trunk side panel trims, flooring, etc. In this regard, Audi believes that in the next few years, the use of recycled materials in vehicle models will increase.

Like the new-generation Audi A3, Polestar Precept also uses renewable materials in the car. It is reported that Polestar Precept uses a new environmentally friendly interior made of high-tech environmentally friendly materials and advanced technology to achieve environmentally sustainable development.

According to the official introduction of Polarstar, the natural linen fiber composite material provided by Bcomp is used in interior panels and seat back panels, which can reduce weight by up to 50% compared to traditional interior parts and reduce plastic use by 80%. In addition, Polestar’s 3D flying line car seats also use renewable materials. The fiber source used is recycled PET plastic bottles. The lining and headrest are made of recycled softwood fibers. The carpet is made of recycled softwood fibers. From recyclable fishing nets. According to the official Polestar, compared with the traditional leather, log and chrome-plated interior, this choice of materials is very groundbreaking.

Volvo has released a new XC60 T8 plug-in hybrid test model that replaces multiple plastic components on the car with renewable plastic. Specifically, the center console of the car is made of recycled fiber and plastic from discarded fishing nets and marine cables, and the carpet is similar to the new generation Audi A3, which contains fibers made from PET plastic bottles and clothing manufacturers ’scraps. Renewable blended cotton material. At the same time, in terms of seats, the fiber made of PET plastic bottles is also used. In addition, the car will also use the old seats on other Volvo cars to make sound insulation under the hood.

BMW’s use of renewable materials is used outside the car, and it uses renewable materials in the X3 cooling air intake parts. It is reported that the part is made of renewable Mafill CR HT 5344 H material. It is worth mentioning that Mafill CR HT 5344 H is Ravago’s first globally standardized recycled polypropylene product. It can provide the same quality regardless of whether it is produced from European or American raw materials.

In addition to the above car companies, Jaguar Land Rover, Mercedes-Benz, Porsche, Toyota, GM, etc. have also used bio-based plastics, bio-based fibers, etc., water-based recycled PU leather, renewable materials in their products. The application of recycled materials in automobiles has a lot of room for development, and it has naturally become the darling of car companies.

The main reason why water-based renewable materials are reused is that they are environmentally friendly, safe and non-toxic, and save resources. Take PET plastic as an example, more than 8 million tons of PET plastic can be reused every year, and its recycling value is extremely high. Because of this, car companies have accelerated the process of converting PET plastics into new materials and applied them to their products.

In addition, greatly improving lightweight, and having excellent performance, Zero VOC and other characteristics are also the reasons for the popularity of renewable materials. At the same time, car companies’ use of these renewable materials has also played a role in promoting their brands. After all, energy saving and emission reduction need to be reflected not only in product emissions, but also in the production process.

Huaian Kaiyue Technology Development Co., Ltd. is committed to the development of environmental protection, mainly produces water-based PU synthetic leather, water-based recycled leather, and water-based polyurethane resin. Water-based products use water instead of organic solvents, do not contain DMF, DOP and other harmful chemicals, (VOC) hazardous chemicals have zero emissions, no pollution during the production process, and environmental protection.

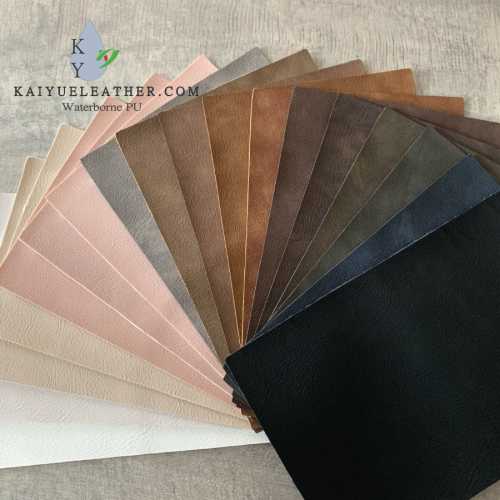

waterborne pu – toffee I

waterborne pu – toffee I

Wax feeling bright surface treatment agent KY209G

Wax feeling bright surface treatment agent KY209G

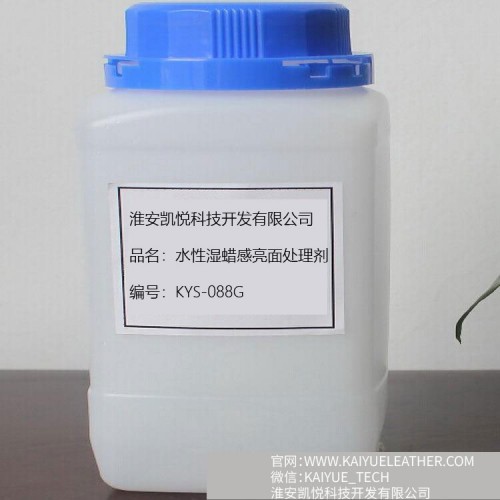

Water-based leather surface treatment agent, Eco-friendly, long-lasting wet wax feel, soft touch, non-slip KYS-088G

Water-based leather surface treatment agent, Eco-friendly, long-lasting wet wax feel, soft touch, non-slip KYS-088G

KY8770 Leather surface treatment agent,Gives leather a smooth feel

KY8770 Leather surface treatment agent,Gives leather a smooth feel

(中文) 金属压铸件的有效脱模剂 烷芳基聚硅氧烷硅油KX-5500效果同DC203

(中文) 金属压铸件的有效脱模剂 烷芳基聚硅氧烷硅油KX-5500效果同DC203

Global Recycle Standard (GRS)

Global Recycle Standard (GRS)

Water-based shoe leather-KY9521

Water-based shoe leather-KY9521

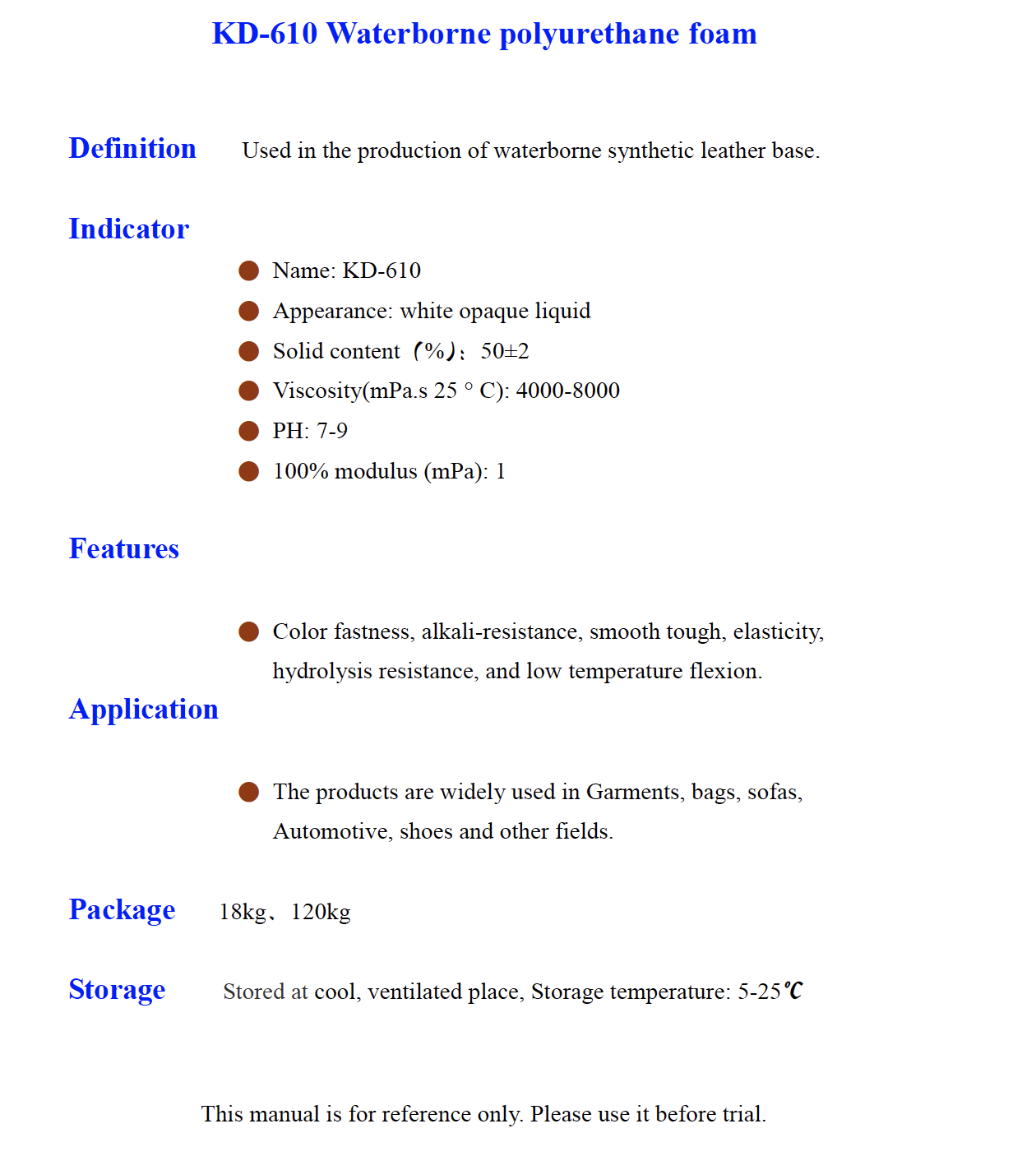

KD 610 Waterborne polyurethane foam

KD 610 Waterborne polyurethane foam