The ingredients of traditional synthetic leather finishing agents are mostly solvent-based, which has the characteristics of low cost and fast drying. Although traditional synthetic leather avoids harm to animals and reduces the destruction of natural ecology, it is prone to produce volatile organic compounds (VOC), flammability and health hazards, causing greater environmental pollution and safety threats. Organic solvents and the VOCs they produce are toxic substances to the human body, which will affect the circulatory system, central nervous system, respiratory system and metabolism of the human body. At the same time, due to the low flash point of organic solvents, special care should be taken in storage and use To avoid production safety risks.

Environmental and safety factors have increasingly become the driving force for innovation and development. The use of water-based leather finishing is imperative, that is, using water as a solvent, non-toxic, non-flammable, does not generate VOC, does not pollute the environment when used, does not cause production safety risks, Does not threaten the health of the producer.

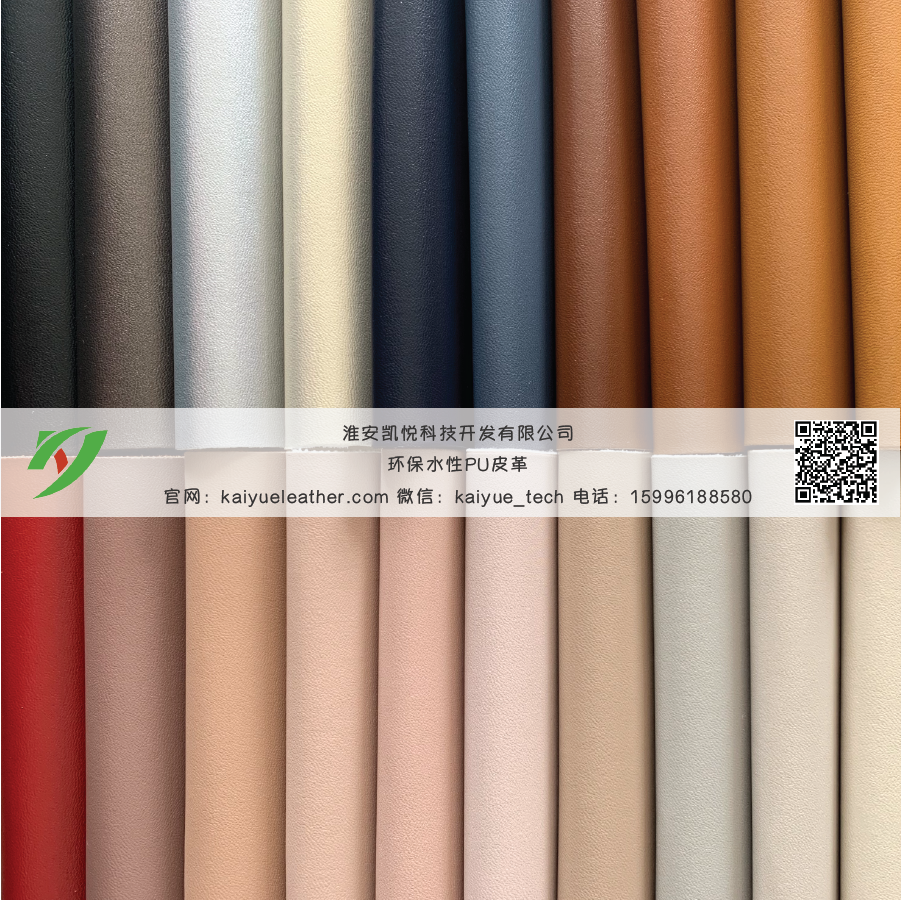

Huai’an Kaiyue Technology Development Co., Ltd. has been engaged in the synthetic leather industry for more than ten years. Following the party’s call, it is committed to research and development of environmentally friendly materials and contribute to society. At present, the company has successfully developed and produced environmentally friendly water-based leather, and has several production lines. What is rare is that KAIYUE Technology independently develops and produces raw materials from water-based polyurethane resin to water-based synthetic leather. It is environmentally friendly and pollution-free throughout the process, and uses pure water-based polymer materials. The chief engineer briefly described the coating method of environmentally friendly water-based leather.

In the coating process used, first of all, the board surface of the fabric should be back-sealed, that is to say, waterproof treatment, the purpose is to avoid excessive resin penetration into the leather board during the coating process, resulting in the phenomenon that the leather board is rigid and the coating feels poor. The back cover material uses water-based waterproofing agent, non-toxic, non-flammable, does not produce VOC, does not pollute the environment when used, does not cause production safety risks, and does not threaten the health of the producer.

When painting, first iron it, and then paint the white paste. The key to finishing the white paste is to do a good job of covering the color flowers and covering the piles. The ratio of water-based polyurethane, acrylic, hand wax, hand agent and filler is improved. , Can improve the covering effect after coating; then paint the paste to further improve the effect of covering the pile; then coat the white paste to improve the physical properties of the surface and the feel of the surface and the permeability of the coating; finally spray Treatment to further improve the physical properties of the surface as well as the feel of the surface and the permeability of the coating.

The advantage of this method is that: first apply white paste on the surface of the fabric board, which can deal with the problems of slight disability, long pile, color flowers and uneven color; after the color paste, apply white paste again, and It can ensure the delicate and transparent feeling of the coating surface, ensure that the product has excellent physical properties, and ensure the style and grade of water-based leather products.

The chief engineer of Kaiyue Technology also said: The company sells waterborne polyurethane resin-waterborne synthetic leather raw materials, providing technical guidance and preparation methods.

For more analysis of water-based polyurethane resins and the use of water-based leather surface treatment agents, please refer to the product system on our company ’s official website Understand.