For the leather industry, the raw material resources used to produce natural leather are limited, and the production of natural leather is a process of high energy consumption and high pollution, which will bring a great pollution load to the environment. In recent years, developed countries such as the European Union have also proposed new standards for the safety of natural leather itself, strictly restricting the presence of toxic substances such as Ct (VI), azo dyes, PCP and free formaldehyde in natural leather. The amount of residual chemicals. From the perspective of raw leather resources, environmental protection, product protection, product safety and market, the production of natural leather is a great challenge.

At present, due to the large amount of chemical treatment agents used in the processing of natural leather and solvent-based synthetic leather from the animal itself, it has caused huge environmental pollution. At the same time, the odor and physical properties of the leather cannot meet the standard requirements of air quality for high-end furniture and car interiors. . Therefore, the market of water-based microfiber leather will have a huge market.

Water-based microfiber is a full-water environmentally friendly microfiber leather production technology. It uses no organic solvents in the entire process. The pure water-based environmentally friendly microfiber leather is absolutely green and environmentally friendly and exceeds the natural leather’s super leather performance Improve the living standards, protect animals and ecological environment and other advantages.

China’s automobile production and sales have been ranked first in the world for ten consecutive years and belong to the world’s largest automobile production and sales country. However, there is a big pain point in China’s auto sales market that has not been resolved, that is, VOC pollutants in automobiles are also a point where consumer complaints are more concentrated. The State also issued the “Guidelines for Air Quality Assessment in Passenger Cars” (GB / T 27630-2011) in 2011, but it is only a recommended standard, and it does not follow these two standards for the air pollution in new vehicles and sales of vehicles Implement control. However, it was revised as a mandatory standard in 2016 and will be implemented from January 1, 2017. With the mandatory landing of the “Guide”, the environmental protection of automotive interiors will definitely bring a wave of market conditions, which will also bring important development opportunities for our water-based microfiber leather.

The latest “Notice on Improving the Application of Financial Subsidy Policies for the Promotion and Application of New Energy Vehicles” clearly proposes that the subsidy period for new energy vehicles should be extended to the end of 2020, and for the first time clear regulations on the scale of subsidies of 2 million vehicles will be made. As a new favorite in the automotive field, new energy vehicles mainly focus on the concept of environmental protection, which coincides with our water-based product concept. The main sources of VOCs in automobiles are interiors such as seats, ceilings, and floor mats. This is exactly the strength of our water-based synthetic leather and water-based superfiber. Especially for ceiling interiors, this technology is currently only available in Toray of Japan. Not only can we replace it perfectly, but the cost can be reduced a lot.

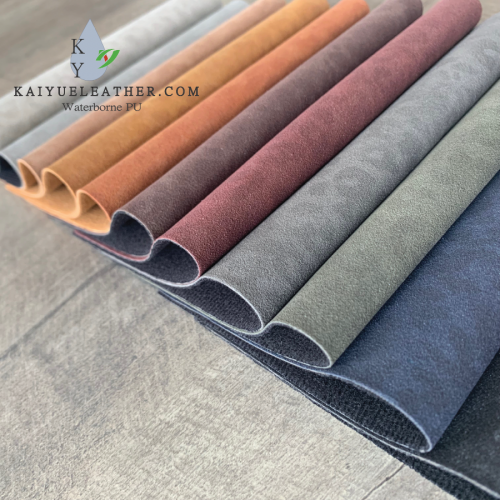

Water-based PU leather-KY9685

Water-based PU leather-KY9685

KY209M Matte treatment agent for leather surface

KY209M Matte treatment agent for leather surface

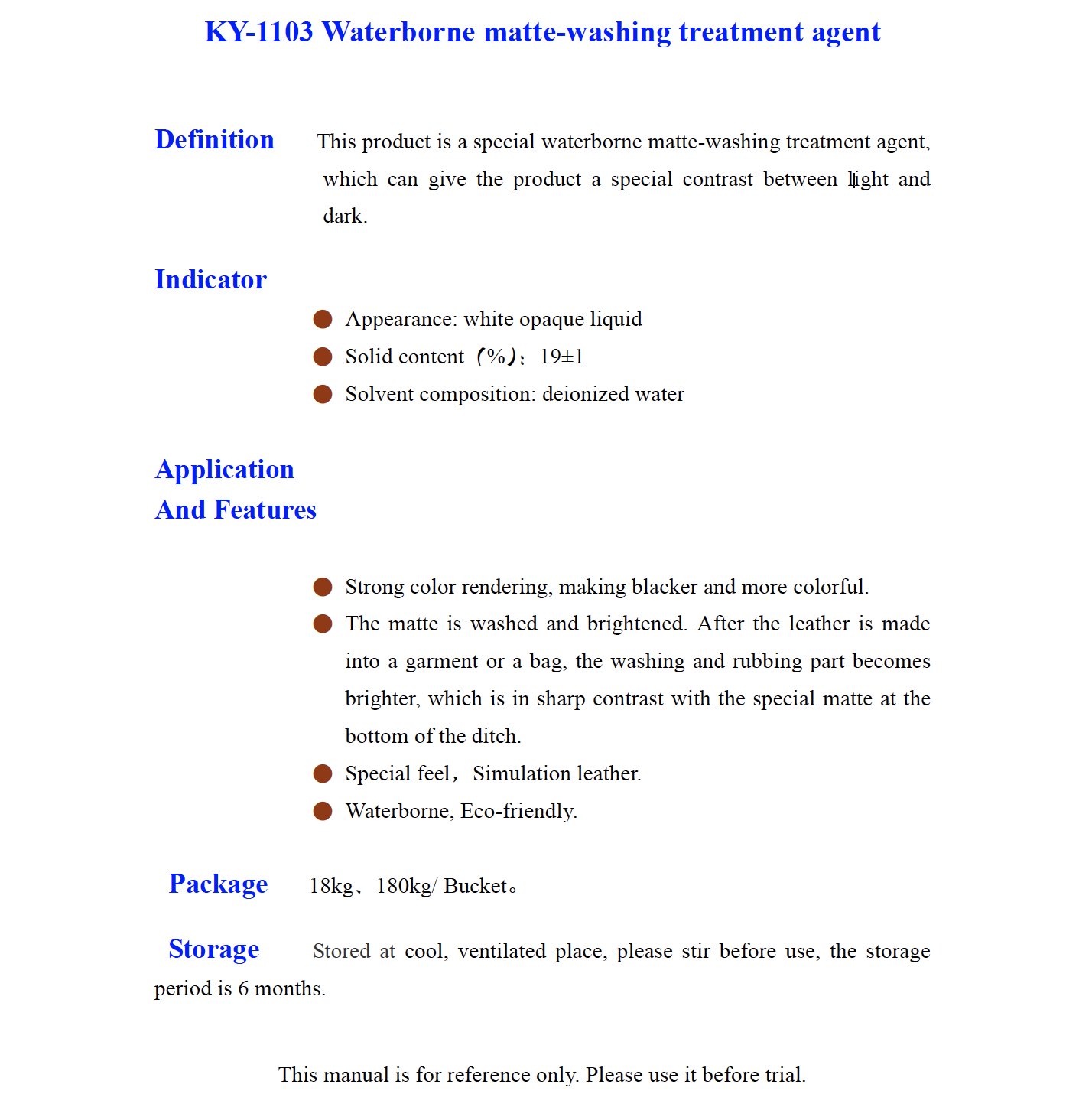

K Y 1103 Waterborne matte washing treatment agent

K Y 1103 Waterborne matte washing treatment agent

Animal skin embossing

Animal skin embossing

KY-307 助剂

KY-307 助剂

Water-based PU clothing leather, children’s raincoat leather, no DMF

Water-based PU clothing leather, children’s raincoat leather, no DMF

KX-ABES-7 Water and oil paint additives

KX-ABES-7 Water and oil paint additives

KL 6116 Waterborne polyurethane bonding layer

KL 6116 Waterborne polyurethane bonding layer