1. The product is non-toxic and harmless

Compared with solvent-based polyurethane synthetic leather, water-based polyurethane not only retains the excellent physical properties, softness and elasticity of solvent-based synthetic leather but also has the unique properties of environmental protection, non-toxic and pollution-free. Therefore, in the synthetic leather industry, the synthesis and application of waterborne polyurethane have received extensive attention and support. Compared with solvent-free, water-based polyurethane has good air permeability and water vapour permeability, pollution-free production process, non-toxic and harmless production materials, and no harm to production personnel. The sanitary performance is significantly better than other types of solvent-free PU coatings.

2. The product has natural hydrophilicity and breathability

Waterborne polyurethane uses deionized water as a solvent and has natural air permeability and hydrophilicity. Products are widely used in shoes, clothing, home improvement, automotive interiors, sporting goods and other fields.

3. The production process is simple and the demand for personnel is small

4. The raw materials are non-toxic and harmless, no harm to production personnel, ultra-low VOC, zero DMF, zero formaldehyde, zero toluene

Water-based polyurethane leather is synthetic leather made of water-based polyurethane polymer materials, which does not contain toxic organic solvents. It is the latest replacement product of traditional solvent-based synthetic leather and a product that conforms to the sustainable development of the world. There is no pollution in the production process, no toxic and harmful waste gas and wastewater discharge. It does not contain DMFa, DMFu, o-benzenes, PAHs, APEO, azo, BPA, formaldehyde, heavy metals and other harmful chemicals. It is healthy and environmentally friendly, and truly harmless to the body. It can meet the latest environmental protection standards of the EU/UK and the United States, and meet the highest environmental protection requirements for synthetic leather at home and abroad.

1. The production process is complicated, the raw materials are toxic, the production contains Isocyanate, and the VOC is not up to standard, which is harmful to the health of production personnel

Traditional organic reactions are often carried out in organic solvents, because organic solvents can dissolve the organic reactants well, make the reactant molecules uniformly dispersed in the solution, and stably exchange energy, but at the same time, the organic solvents are toxic, volatile, and The difficulty of recycling makes it a harmful factor to the environment; in particular, many of the pollution of the earth’s ecological environment is related to the production and use of chemical substances synthesized by organic solvents used by humans. The use of solvent-free PU resin to produce synthetic leather does not use organic solvents. Essentially, in the process of producing solvent-free synthetic leather, components A and B need to be used. During the production process, a large number of highly toxic substances may be volatilized, and free residues may remain in the product. Isocyanate.( On October 27, 2017, the list of carcinogens published by the International Agency for Research on Cancer of the World Health Organization is a preliminary collation reference. Isocyanate is in the list of 2B carcinogens). Therefore, compared with solvent-based synthetic leather, solvent-free synthetic leather is more environmentally friendly, but the production process still contains carcinogenic and highly toxic substances. Because TDI is extremely volatile, it can pass the REACH standard of SGS when the product is sent for testing, but TVOC cannot meet the synthetic leather application standards of European and American countries. (TVOC is the abbreviation of “Total Volatile Organic Compounds”, which means total volatile organic compounds.) Indoor air quality researchers usually call all indoor organic gaseous substances they sample and analyze as TVOC, which is three Volatile Organic Compounds The abbreviation of the first letter of the word, various measured VOCs are collectively called TVOC (Total Volatile Organic Compounds). TVOC is the more serious one among the three types of pollution that affect indoor air quality. TVOC refers to organic matter whose saturated vapor pressure exceeds 133.32pa at room temperature. Its boiling point is between 50°C and 250°C. It exists in the air in the form of evaporation at room temperature. Its toxicity, irritation, carcinogenicity and special odor Sex, can affect the skin and mucous membranes, and cause acute damage to the human body. The World Health Organization (WHO), the National Academy of Sciences/National Research Council (NAS/NRC) and other institutions have always emphasized that TVOC is an important type of air pollutant. The U.S. Environmental Agency (EPA) defines VOC as: except for carbon monoxide, carbon dioxide, carbonic acid, metal carbides, carbonates and ammonium carbonate, any carbon-containing compound that participates in photochemical reactions in the atmosphere. )

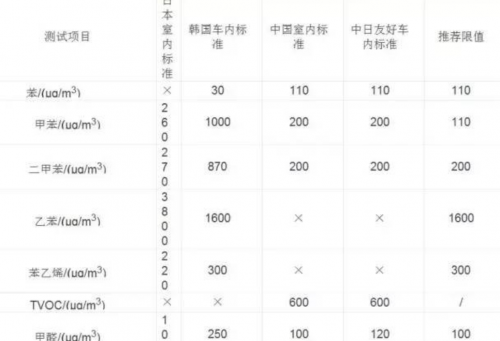

The history of my country’s automotive VOC testing standards

At present, there are only two direct standards related to automobile VOC issued by my country, namely HJ/T 400 “Methods for Sampling and Determination of Volatile Organic Compounds and Aldehydes and Ketones in Vehicles” and GB/T 27630 “Guidelines for Air Quality Evaluation in Passenger Cars” .

2. The product is not breathable

Due to solvent-free raw materials and structure, solvent-free synthetic leather products are not breathable. This feature is not applicable in many areas of synthetic leather industry applications, such as shoemaking, clothing, home improvement, automotive interiors, etc. This is why the new environmentally friendly synthetic leather required by developed countries such as Europe and the United States requires water-based polyurethane synthetic leather.

3. Single product appearance

In the previous Hyatt article, the structure of synthetic leather was mentioned. The wet PU leather is composed of five layers: base fabric, an adhesive layer, foam layer, surface layer and surface treatment layer. Solvent-free synthetic leather can only be used as a bonding layer. There are still many application technologies that need to be solved to be coated on textiles. At the same time, problems such as hand feel, physical properties, style, texture, etc. must be achieved…especially to achieve or It needs a lot of work to exceed the quality of the existing wet-process PU synthetic leather. Solvent-free synthetic leather itself, as an environmentally friendly synthetic leather product, also urgently needs environmentally friendly supporting raw materials. If solvent-based surface treatment agents are still used, their development significance will be largely lost. Therefore, if you want the pattern effect of the surface layer, you still need to use water-based polyurethane and water-based surface treatment agent.

In summary, what are the main differences between water-based and solvent-free synthetic leather?

Water-based polyurethane synthetic leather is more environmentally friendly from raw materials to product acceptance, has natural breathability and hydrophilicity, and is suitable for shoes, clothing, home decoration, automotive interiors, sports goods and other fields. Solvent-free products are suitable for polyurethane sole materials.

Huaian Kaiyue Technology Development Co., Ltd. independently develops and produces raw materials to finished products. Water-based polyurethane resin, water-based leather surface treatment agent, water-based polyurethane synthetic leather.

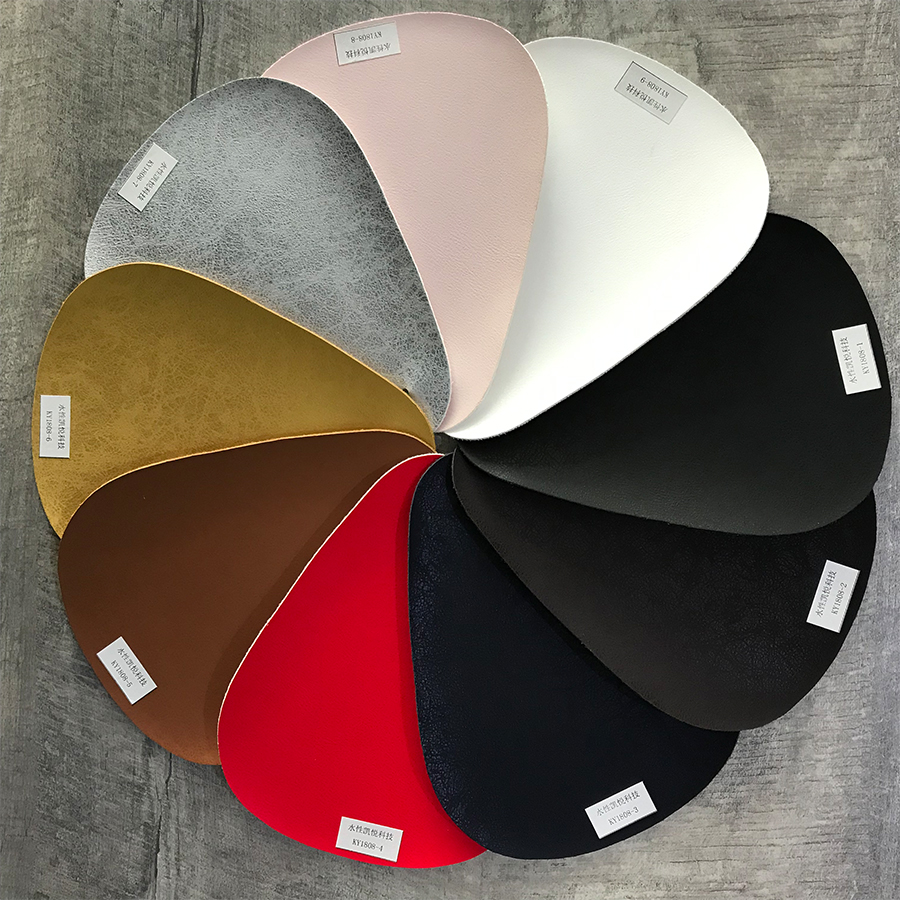

Waterborne PU for Handbag

Waterborne PU for Handbag

For Handbag&Shoes&Furniture III

For Handbag&Shoes&Furniture III

(中文) 金属压铸脱模剂用改性硅油 烷芳基硅油 KX-V1100 如DC203

(中文) 金属压铸脱模剂用改性硅油 烷芳基硅油 KX-V1100 如DC203

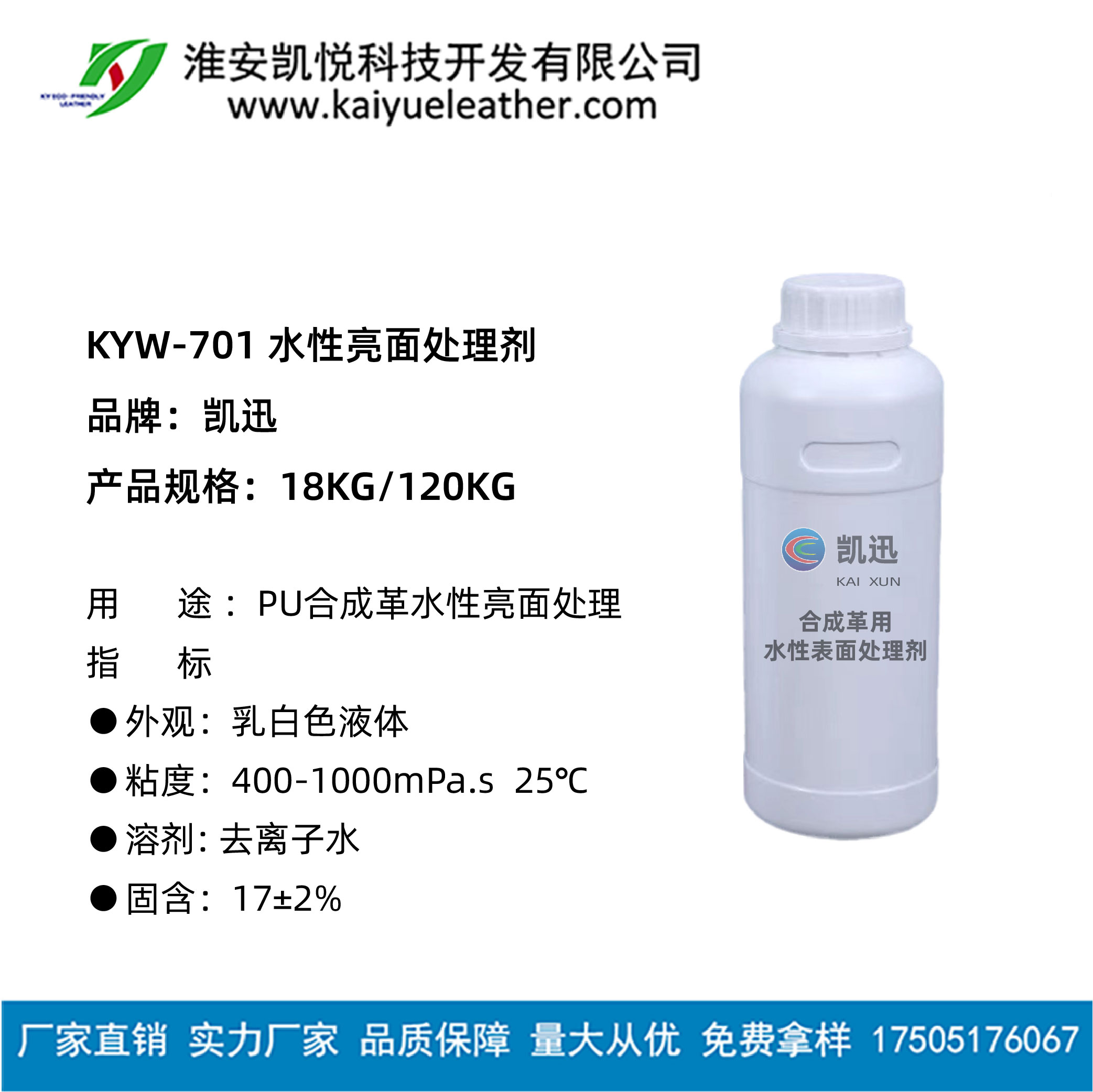

water-based brightening treatment agent

water-based brightening treatment agent

Dermal surface agent, wet waxy matte surface treatment agent KY088S

Dermal surface agent, wet waxy matte surface treatment agent KY088S

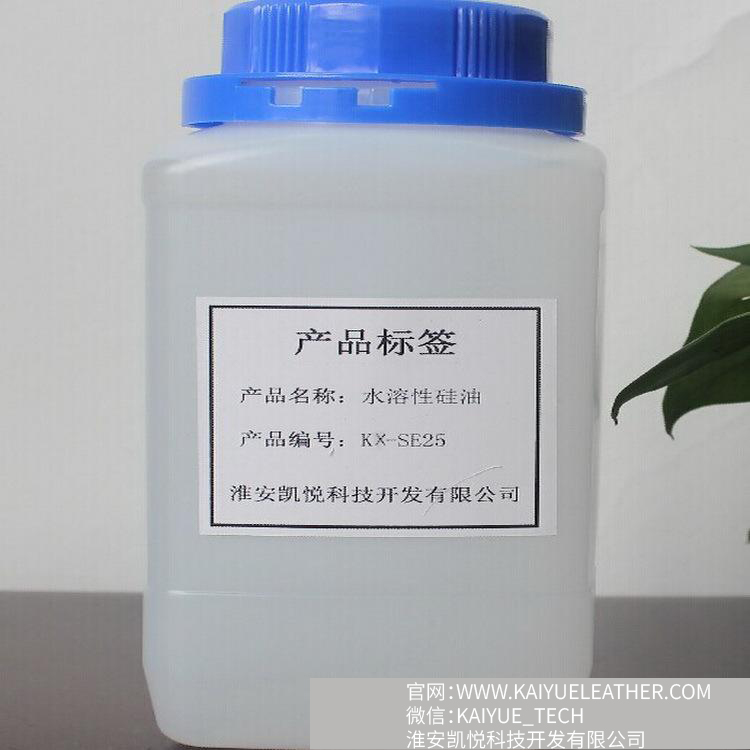

KX-SE25 Water-soluble silicone oil

KX-SE25 Water-soluble silicone oil

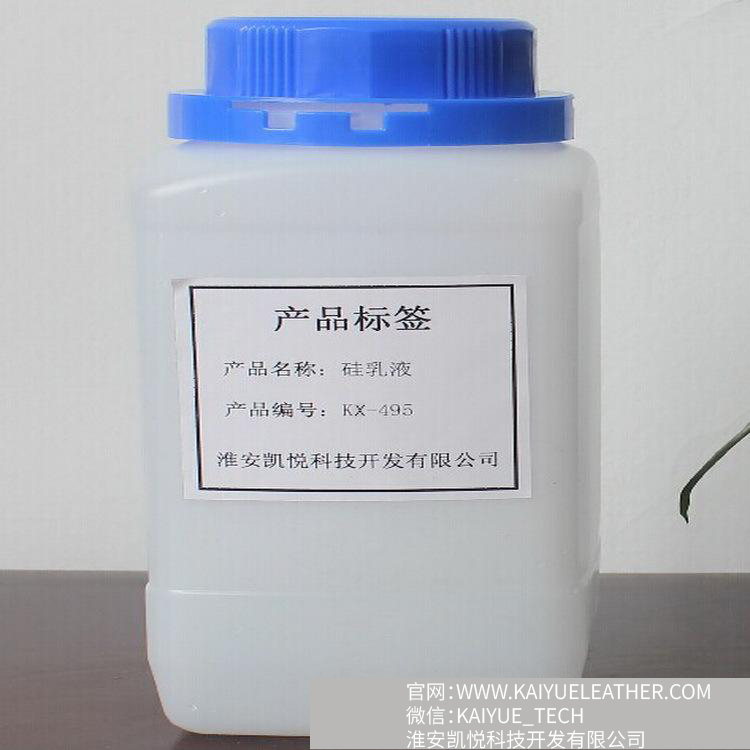

Water-based rubber plastic mold release agent 40% anionic emulsion KX-495 Kai Xun

Water-based rubber plastic mold release agent 40% anionic emulsion KX-495 Kai Xun